Werkzeugbau Berger - traditionally innovative

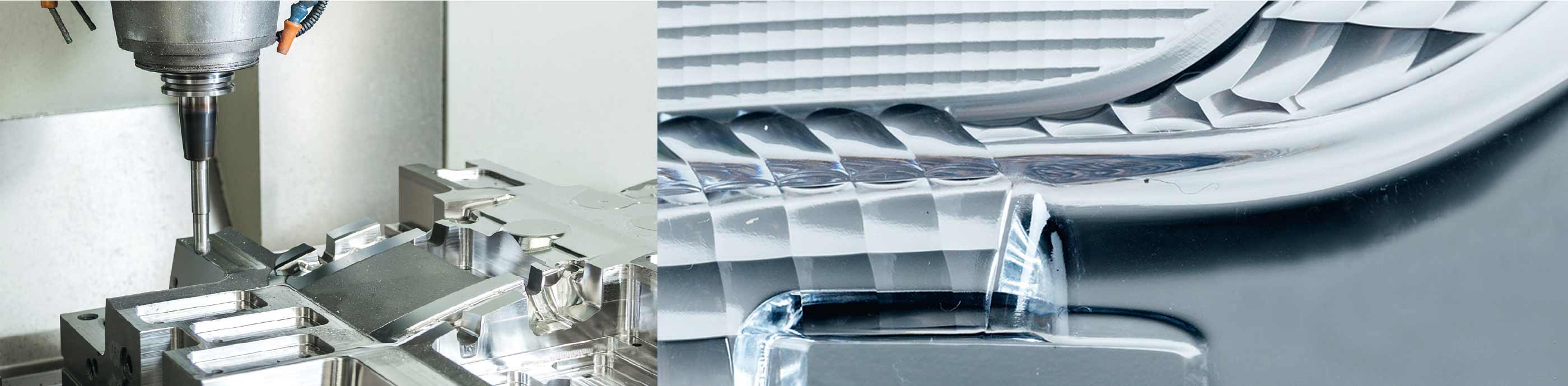

Our innovative and high-quality products are used in complex production processes worldwide. Throughout the last years we have more and more specified in the production of injection molding tools for components with light function and highly-decorative parts as well as technical parts for the automotive industry with high requirements regarding tolerances and accuracy.

„Since foundation of the company in 1969 Werkzeugbau Berger GmbH has become a well-known specialist for the development, construction and production of high-end precision tools in various industries.“

But also the production of die casting molds for the processing of zinc, aluminum and magnesium is our business. As a traditional family-owned company partnership, reliability and solidity are parts of our corporate culture. To react to our customers’ needs even more flexibly in the future, we have recently reorganized and expanded our production. Thus we can offer customers high-quality products at competitive prices and short lead times.

Here you will find a compact overview of our core competencies, service portfolios and unique technological features

➔ Download company brochure

➔ Download company flyer (german)

The team

A high qualification and motivation of our employees is very important for us. We give them the opportunity to develop themselves to take responsibility. Currently more than 55 experts belong to our team

With great effort and accuracy we face the complex challenges of the daily business. As a medium-sized family owned company, mutual cooperation, self-responsibility and fast decisions play an important role for us.

The cooperation of young and experienced staff ensure a friendly and family-like atmosphere. This is an important basis for high performance and outstanding quality. For our customers we want to make the impossible possible. Therefore we have our motivated and well-adjusted team.

Quality first

In addition to our long-term experience and high qualification level of our employees, the use of state-of-the-art technologies is a cornerstone.

From the component development and tool design using CATIA to CAM programming and the process of mechanical milling, sink eroding and wire cutting to the compilation and qualification of the ready to produce equipment, we use modern technologies.

Due the high level of vertical integration in-house we can respond to customers’ needs quickly, flexibly and independently. Reliability and in-time delivery are a matter of fact for us and integral part of our corporate culture. For the purchase of external deliveries and services we have been able to gain reliable cooperation partners throughout the years.

We guarantee the accordance with high-quality standards. Werkzeugbau Berger GmbH is certified according to the high standards of the quality management system DIN EN ISO 9001.

Value Proposition

-

Quality

Our tools are developed and manufactured to the highest quality standards. This enables us to guarantee you maximum durability.

-

Precision

With over 50 years of experience in lighting technology, we are able to manufacture tools with a very high degree of accuracy and surface finish in order to meet our customers' requirements for their end products.

-

Reliability

We ensure that your tool is delivered on time and in accordance with the agreed specifications.

-

Customer support

We offer comprehensive support and advice throughout the entire process, from planning to after-sales service.

-

Cost efficiency

We offer solutions that are not only high quality but also economical as a service with the aim of increasing added value for the customer.

-

Flexibility

It is important to us to respond to individual customer requests and implement them.

Certificates & Proofs

ISO 9001:2015 – Quality Management

Certification of our process-oriented quality management system in accordance with ISO 9001:2015.

Focus: stable processes, reproducible results, documented quality assurance and continuous improvement.

360° Sustainability Check

Comprehensive analysis of ecological, economic and social fields of action.

The 360° check identifies potential for optimisation and serves as a basis for strategic sustainability initiatives and internal developments.

Ecovadis – Sustainability rating

External assessment of our sustainability performance in the categories of environment, labour and human rights, ethics and sustainable procurement.

The Ecovadis rating confirms our focus on responsible and sustainable corporate management.

Policies & Guidelines

Code of Conduct

Our binding principles for responsible, compliant, and sustainable conduct throughout the entire value chain.

Supplier Code of Conduct

Operational requirements for our partners with regard to quality, compliance, process stability, and integrity.

Memberships

VDWF – German Tool and Mould Makers Association

Membership in the VDWF to actively shape industry-specific standards, promote professional exchange, and strengthen networking within the tool and mould making sector.

➔ Visit the VDWF website

BVMW – Federal Association of Small and Medium-sized Businesses

Active involvement in the BVMW to expand our network within the industrial SME sector, exchange insights on economic developments, and gain access to relevant innovation and funding topics.

➔ Visit the BVMW website

Innovation & Development Initiatives

MES Integration ProLeiS (Tebis Group)

Implementation and phased rollout of the MES system ProLeiS for end-to-end digital mapping of the entire production chain. Objectives: increased process stability, consistent data across all systems, transparent resource utilization, and reliable, KPI-capable shop floor reporting. The integration is modular and supports the scaling of future digitalization stages.

➔ View the case study (german)

POLYWISE Research Project

Requirements for sensors and data transmission are rising – especially in the high-frequency range beyond 100 GHz. This is precisely where POLYWISE comes in: The project aims to develop innovative polymer-based dielectric waveguides (DWG) that replace metals, conserve resources, and unlock new application potential.

➔ Download the project description (german)